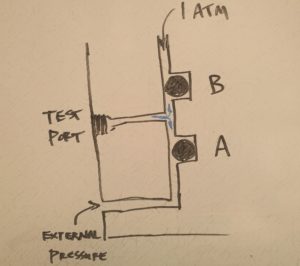

In last week’s tip, I confirmed that in the diagram below, the primary seal is Seal B and that Seal A is NOT redundant.

This week’s final tip on connector seals and test ports pertains to the test port itself.

Recall from previous tips that the test port is itself a potential leak path, which is why Seal B is the only seal that really matters in the above configuration. But that test port is more than a potential leak path. It can also act like a cheese grater.

We’ve seen from personal experience that if you don’t chamfer or otherwise break the sharp edges of the test port (in the diagram above, this is the portion of the test port between Seal A and Seal B) you will clip Seal B every time you insert or remove the connector. Why? Because the seals get energized upon entry of the connector in the port, and whenever Seal B passes the test port opening, that portion of the seal de-energizes to fill the gap and will get clipped on any sharp edges as a result, as seen in the photo below of a FCR-type connector:

Another way to avoid clipping altogether is to use a connector where the diameter of the connector below the test port is smaller than the diameter of the connector above the test port. This way, the primary seal passes by the test port without ever making contact.

We hope you have gotten some use out of these past few tips regarding connector seals and test ports.

© 2017 by LinRich Solutions, LLC. All rights reserved