“Plan The Promise” is a phrase we coined which means, at its most fundamental level, to plan out in detail whatever you’re about to promise to your client(s). It means doing your due diligence and making smart commitments on behalf of your business. To be able to do your due diligence, it also means treating project management as a core competency in your business. I’m confident that if you’ve been around the Oil and Gas industry long enough, you’ve personally seen or experienced at least one project where promises for a certain delivery date and price turned out to be one great big (unintentional?) lie. The problem isn’t just isolated to specific elements within the Oil and Gas supply chain, such as manufacturing (although this is where we’ve gotten most of our bloody t-shirts).

Let’s take a look at what happens when we don’t Plan The Promise. For this example, pretend we work in an Oil and Gas product manufacturing business.

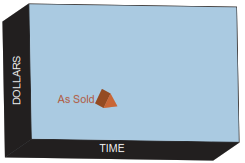

ORDER—When we first receive a customer’s purchase order, we are aware of three things: the expected cost, the promised ship date, and the expected profit. But was the as-sold cost and ship date derived

from detailed planning and scheduling? Can we assume that there is a plan to track organizational performance over the life of the project? Typically, the answer to both questions is, “no.” On the first graph, we mark “as-sold” next to the orange triangle which is the expected cost and delivery date. Notice that there is just a single point in space and that there is no s-curve (performance measurement baseline) leading up to this single point. Put another way, there is no understanding of how and when the costs/effort are going to accumulate as we approach the promised ship date. There’s nothing to track to.

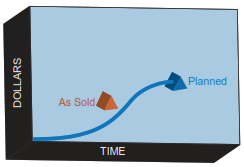

FULFILLMENT—After the order is taken, the fulfillment process starts. In most manufacturing organizations, this is when a project manager (PM) typically gets assigned to the order. The PM eventually develops some semblance of a plan and starts to discover what it should take for the organization to deliver the product. At this point it starts to become obvious that the project won’t meet expectations. Graphically, this is represented by the blue s-curve. Notice that the planned cost and time exceed what was originally promised. But to make matters worse, even though we now have an s-curve to track performance against, rarely is this curve a good predictor or baseline for what will actually happen.

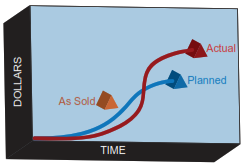

DELIVERY—What really happens is depicted in the red line on the third graph. The costs and delivery date changed even more than what the project manager originally predicted. Not only were we late and our customer was beyond irate, we likely didn’t meet our profit expectations. It’s even possible that we lost money on the order.

WHY DOES THIS HAPPEN?—There are many reasons for the huge delta between the as-sold, plan and actual dates and costs. In our experience, the main culprits are:

- What needed to be done by the organization was not discovered until after the order was taken (the scope was never fully and completely defined ahead of time)

- Things that had gone wrong in the past were not accounted for in the estimating (risks that should have been accounted for but were never considered)

- There was no plan for how to address the inevitable scope changes that happen on most projects (no controlled change management process)

- The organization regards project management as just another enabling skill set (project management is not treated as a core competency)

- The organization uses ad-hoc project processes, procedures, tools and techniques (project management system is not formalized)

- Project change isn’t anticipated nor controlled, it’s purely reactive

SO WHAT CAN BE DONE?—I think it starts at the top. Does project management report directly to the CEO as a core competency, or is it “siloed” down in the business units as just another skill set? Are projects viewed as a vehicle for implementing corporate strategy? Is there somebody responsible for ensuring consistent project management practices across the enterprise? Are project managers professionally certified and do they have a career path? Is project management involved in the sales process? (By the way, bids and proposal teams aren’t necessarily the panacea—they’re sometimes a separate, autonomous group that can become disconnected from the reality of those who execute the work order(s).) Are project managers responsible for managing project costs?

Even if none of the above questions can be answered satisfactorily, there’s still hope. Before you give your customer the next quote, loan your most senior, professionally trained project manager to your sales team and have him/her do the detailed planning with the people who will do the work. You’ll need about 30% of the project’s total duration to properly Plan The Promise.

© 2016 by LinRich Solutions, LLC. All rights reserved